HMS Hood carried 5 UP launchers when she was sunk (UP stands for Unrotated Projectile.). These weapons could fire 20 3inch rockets containing so-called aerial mines. These mines had a 238 gram explosive charge tethered to a parachute in the hope that an enemy pilot was polite enough to hit them. However, this actually never happened with the 60 units placed on various ships. The model is based on John Lambert’s drawing no. L/0/96, but this drawing contains one error; the sloped-back glacis plate was not in the drawing. The drawing did contain enough information to design a few etched parts so that some wonderful detail can be added.

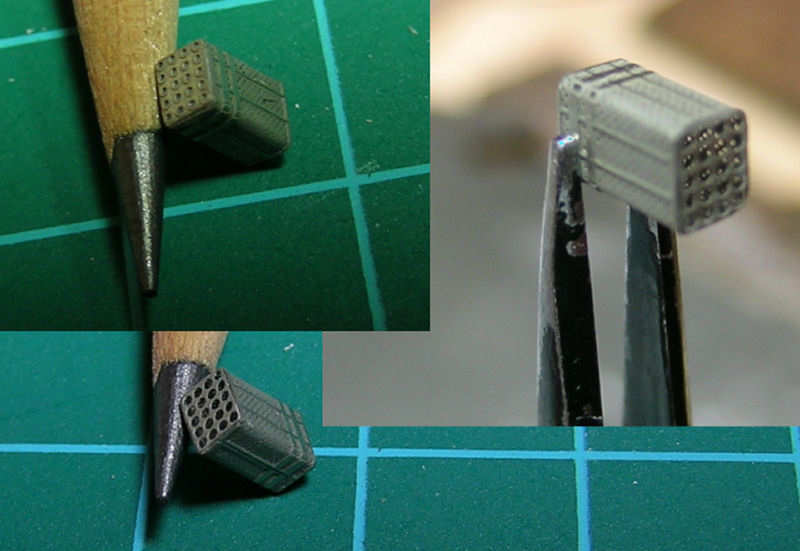

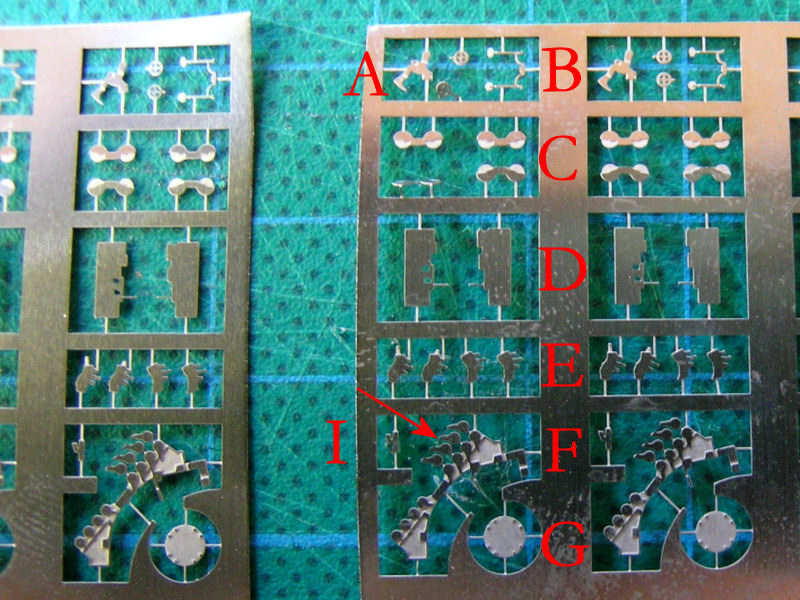

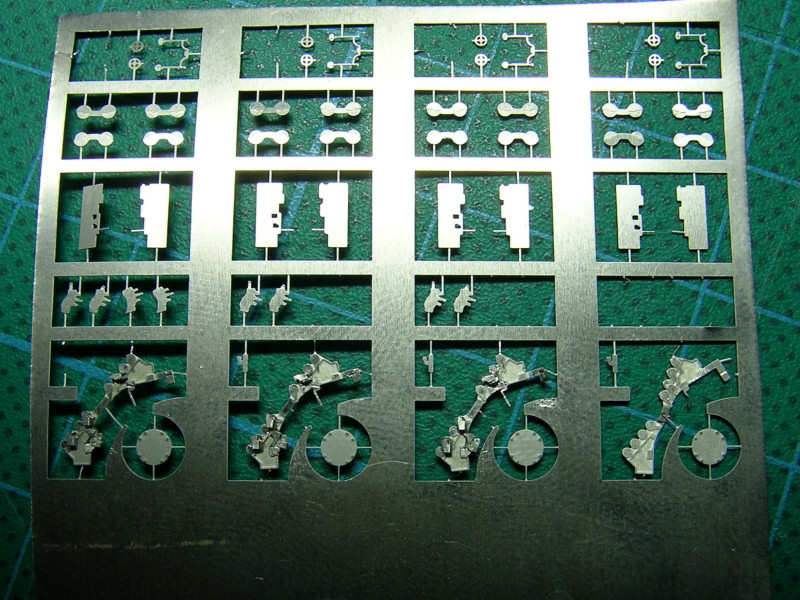

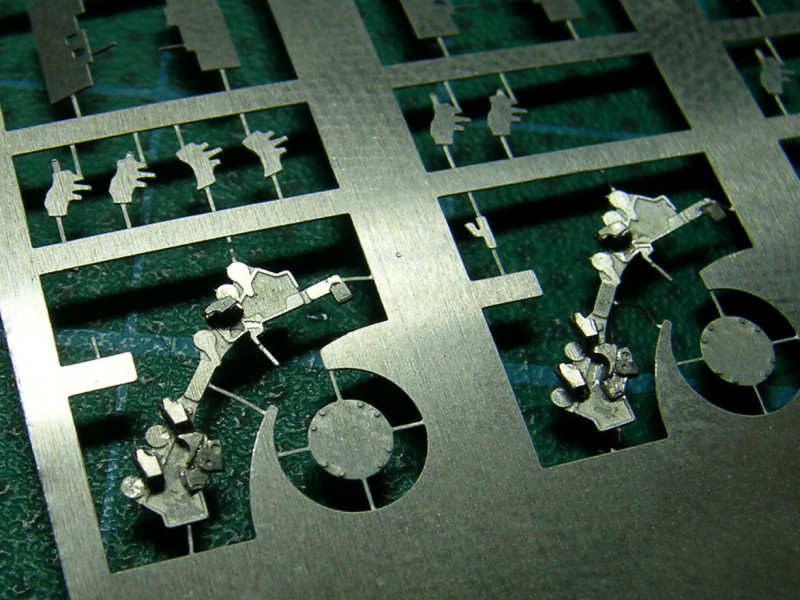

The edges of the etched part folded around the launch tubes is not 90 degrees, but actually two 45 degree angles. Folding the part to size wasn’t very easy (I did use a cut-to-size fold mould) and the first folding attempt proved to be difficult. Using styrene as a filler and then drilling in the tubes using the front as a template didn’t work out either as I frequently drilled right through the etching so in the end I cast the part without the front etching. I hadn’t cast anything lately, so I order some CR-600 casting resin and 1-to-1 mold rubber from Micro-Mark. These products mix on a 1 to 1 basis, so you can mix by volume and avoid many casting disasters when preparing small batches. All the detail of the etched part is retained perfectly in the casting. I drilled in the launch tubes using a drill-press with a positioning table at the workshop at work. The tubes are 0.5mm with a spacing of 0.6mm, so that’s only 0.1mm between the ‘tubes’. Small errors show up immediately if you’re off by the slightest amount.

I forgot to cast a block to hold on to the part when using the drill press and I also lost quite a few castings due to errors in drilling or handling. I guess I cast and drilled in over thirty parts before ending up with five acceptable parts.

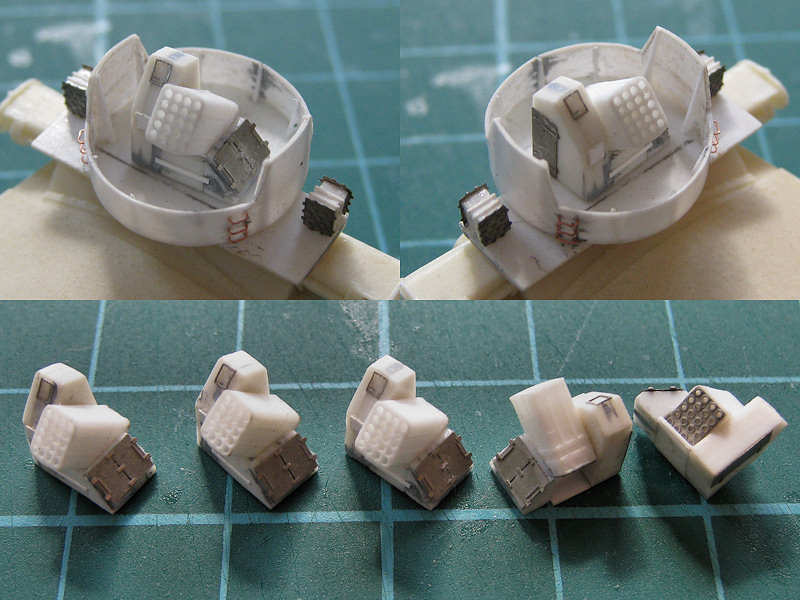

Here is one model protected by splinter shields atop B-turret. A door is present on the armoured operators cabinet, including the sighting window. A hatch is present on the other side of the model, probably an access hatch to the traversing mechanism. An etched part is added to the bottom of the launch tubes (not on the pic). The ammo boxes are based on photographs of HMS Hood.