Note, the type III designation is my own

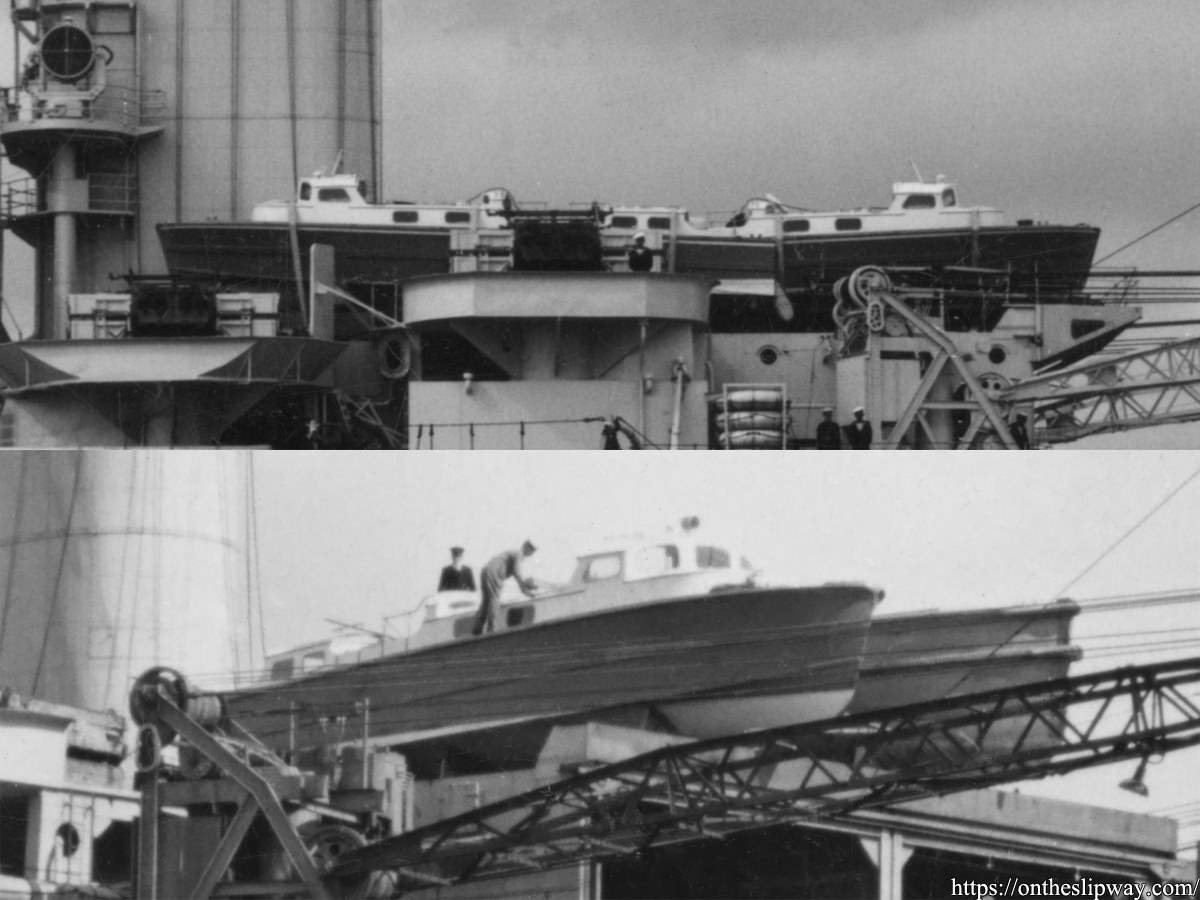

The 45ft Fast Motor Boats of HMS Warspite

The 45ft Fast Motor Boats of HMS Warspite

During her 1931 Spring Cruise, HMS Nelson passed through the Panama canal. February 22nd she left from Kingston, Jamaica, and on the 23rd she arrived to receive a pilot and a US Liason officer. She suffered some minor damage entering the Pedro Miguel Lock, but finally berthed at Balboa for five days of festivities and ceremonies including a visit of her officers to the battleship USS Texas. On the 28th she made a return trip through the canal [1].

[1] McCart, N., Nelson & Rodney, 1927-1949, The big battleships, Maritime Books, 2005

Below are a number of postcards; the quality of good enough you can read the name of the locks on the small buildings (on the scan that it).

Entering the first Gatun lock at the far North of the canal

Entering the second Gatun lock.

Passing the Gaillard/Culebra cut

Entering the first Miraflores lock at the far South of the canal.

There’s a spectacular range of images of the event taken from the shore at the Naval History and Heritage Command website, and when I look a bit closer at image NH-57847 I believe I can spot the camera man on the bridge who took the above photographs.

Copyright © 2025 On The Slipway

Theme by Anders Noren — Up ↑