A small how-to on cutting steel tubing at very small sizes accurately. I bought mine from Cammett Ltd (update 2021: I switched to Albion Alloys micro-tubes that is a much nicer material to work with). The tubing comes in a wide variety of inner and outer diameters and can be most useful for small detail work.

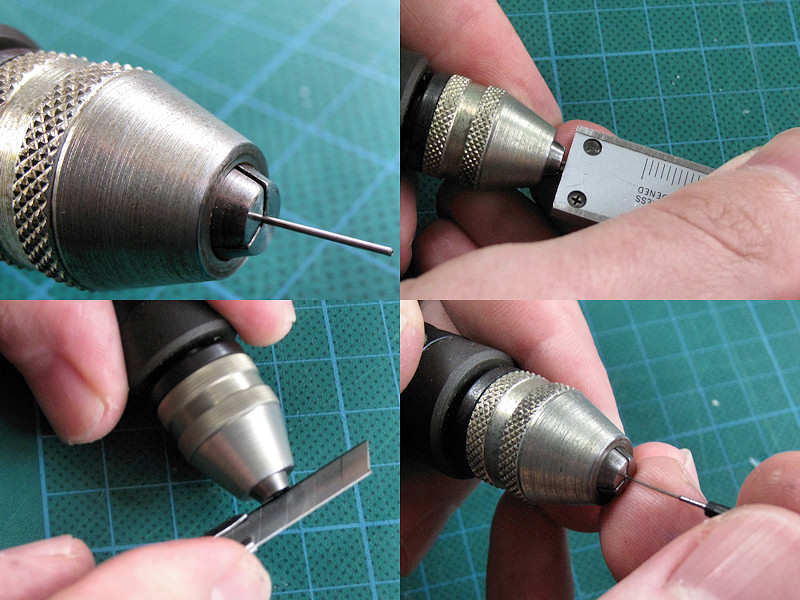

I start cutting of a bit of tubing and inserting it into the chuck of my drill. Both Proxxon (28941) and Dremel (4486) offer these chuck as a affordable accessory to their drills next to their range of collets. At this point I usually sand down the tube. I then use the depth probe of my caliper to insert the tube into the chuck with the to-be-cut tubing sticking out at the right distance. The drill is switched on and I use a sharp knife to cut off the tubing in a sawing movement. I do this carefully, as the part sometimes jettisons away. Don’t try to hold the part in place using a finger, you might inadvertently drill yourself. After the tube is cut, I use a precision reamer to clean the remaining tubing. I do this by hand, I lost a few reamers with the drill turned on. Positioning the reamer is probably the hardest part.

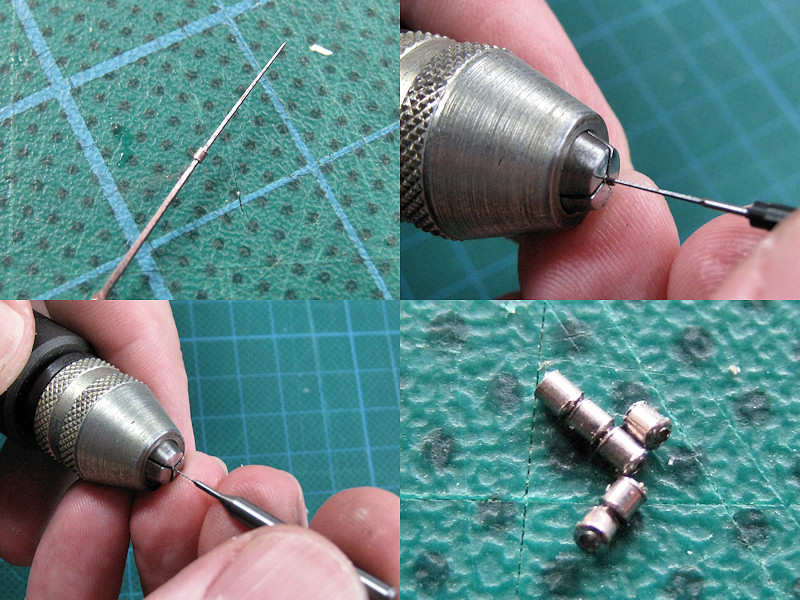

Now the small tube needs to be cleaned, but it can be very small and near-impossible to hold. I use the reamer to pick up the tube and reinsert into the chuck. I apply the reamer when the tube is again firmly in place and a drill to check if the outer diameter is larger enough after cleaning (and for drilling). Sanding down the part at this point is also possible. At the end you have small pieces of tiny tubing at a consistent size. Using the macro setting of my camera shows the edged are a bit rough, but it’s a 0.5 by 0.5 mm part.