16/03/2025

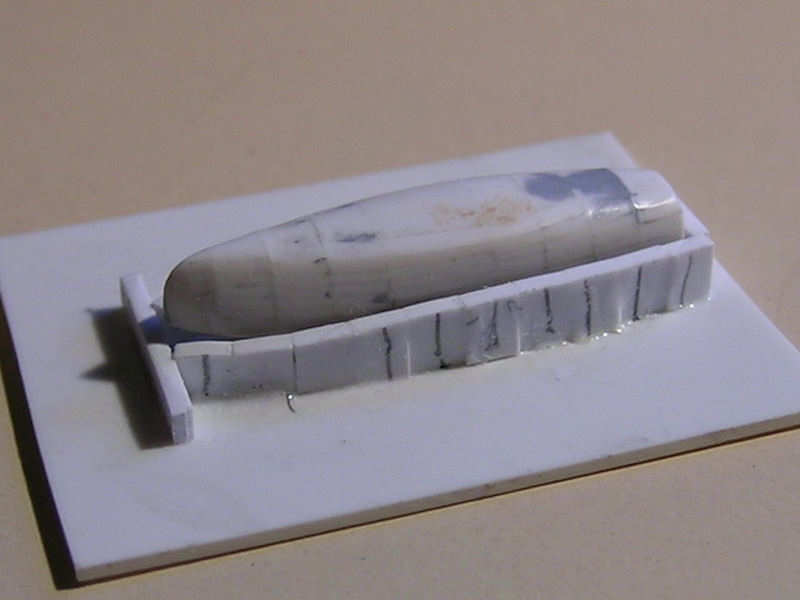

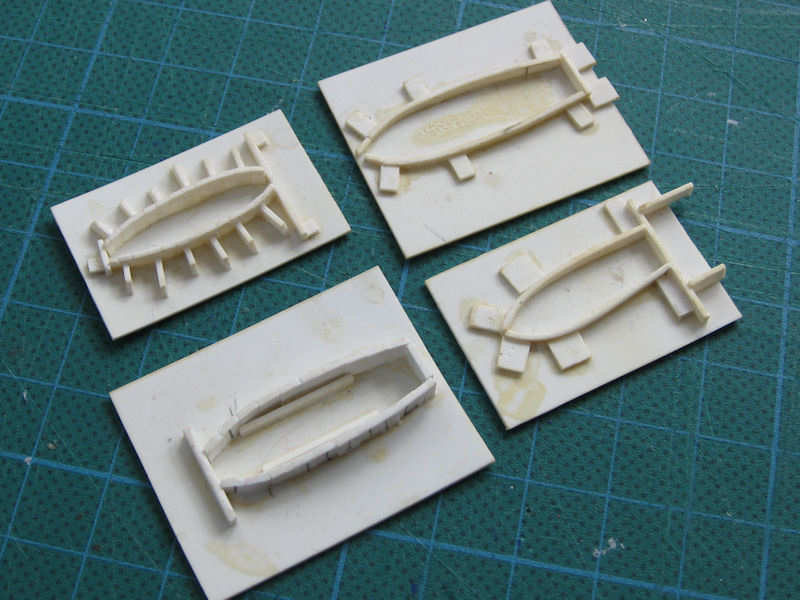

– Added 45ft Fast Motor Boats type III, 4 images

– Added 35 ft Vospers Admiral’s barge, one image

15/03/2025

– Added 3 images of the 35 ft Fast Motor Boat, Admiral’s barge version

– Added 1 image of the 35 ft Fast Motor Boat, Vospers version

14/03/2025

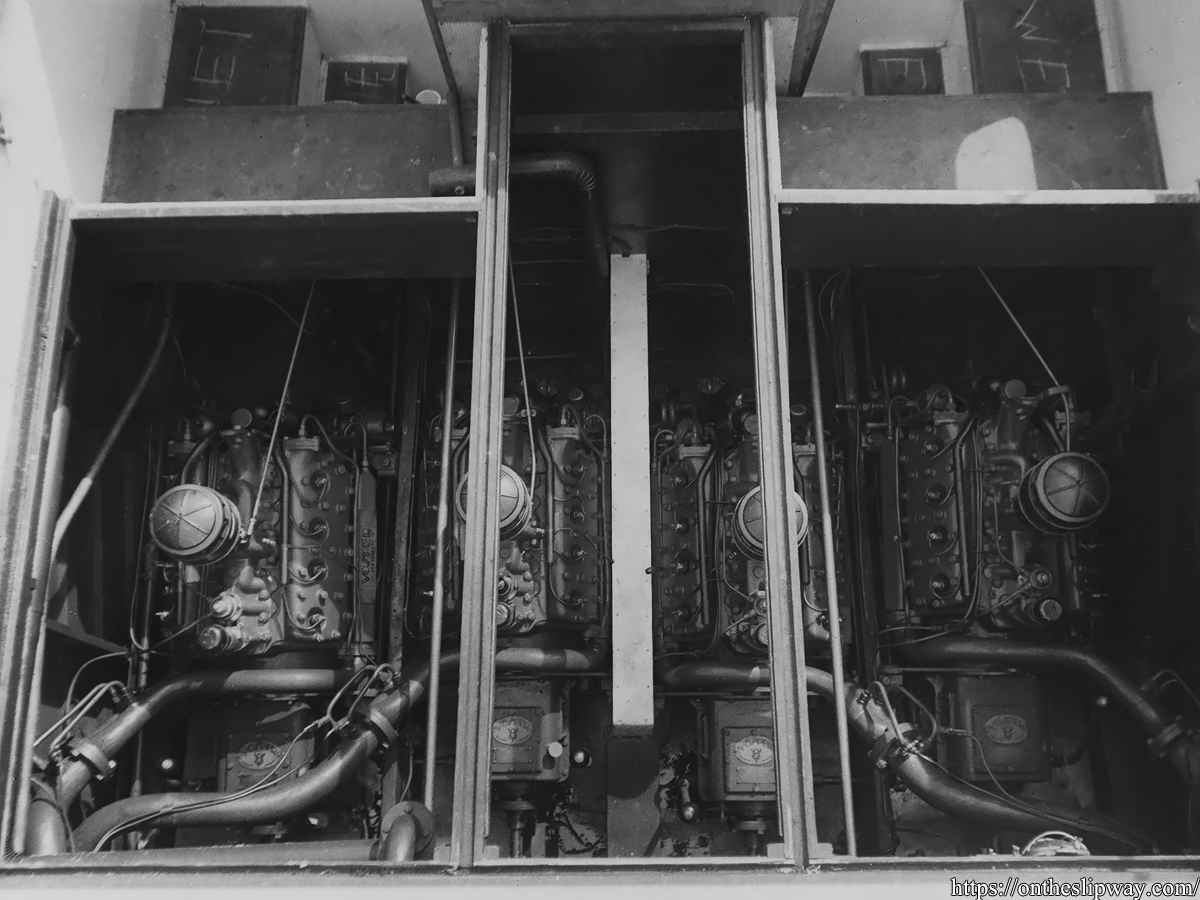

– Added 2 images of the 40 ft Royal Barge (trials, engine compartment)

09/03/2025

– Added 2 images of the 35 ft Fast Motor Boat, HMS Devonshire)

– Added 5 images of the 32 ft Cutter, HMS Devonshire)

13/09/24

– Added 2 images of the 50 ft steam pinnace (HMS Royal Sovereign)

– Added 1 image of the 45 ft admiral’s barge (HMS Warspite)

15/06/24

– Added 1 image of a 45 ft Motor Launch (standard type)

22/03/24

– Added 1 image of HMS Renown’s 45 ft Motor Launch (light type)

12/02/24

– Added 2 images of HMS Dorsetshire’s 35ft Motor Pinnace

07/10/23

– Added 1 image of HMS Prince of Wales’ 25ft FMB (presumably)

01/10/23

– Added two scans of drawings of the 32 ft cutter (from McDermaid & Manual of Seamanship)

21/09/23

– Added 1 image of the 40 ft Royal Barge (rear view, trials)

04/09/23

– Added list of yards to main boat page as a reminder; to be appended

– Added 1 image of the 32 ft cutter (HMS Hood)

– Added 1 image of the 50 ft steam pinnace (HMS Hood)

03/09/23

– Added Vospers advert to main boat page with ID’s insofar as I can determine

– Added placeholder for 20 ft Fast Tender

– Added 4images of the 32 ft cutter

11/08/23

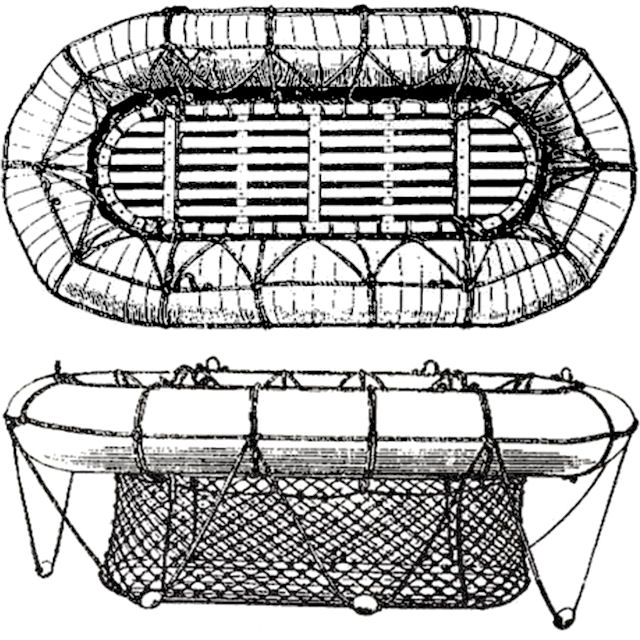

– Added 1 IWM link(Q 18011) to balsa raft

– Added 1 IWM link (A 7776) 45 ft Motor Launch (light type)

– Added 32ft cutter plus link to Albatross pdf

08/08/23

– Added scan from Newton clinker/carvel/diagonal defs

05/07/23

– Added 1 IWM link (A1519) of HMS Revenge’s 45ft standard type launch

03/04/23

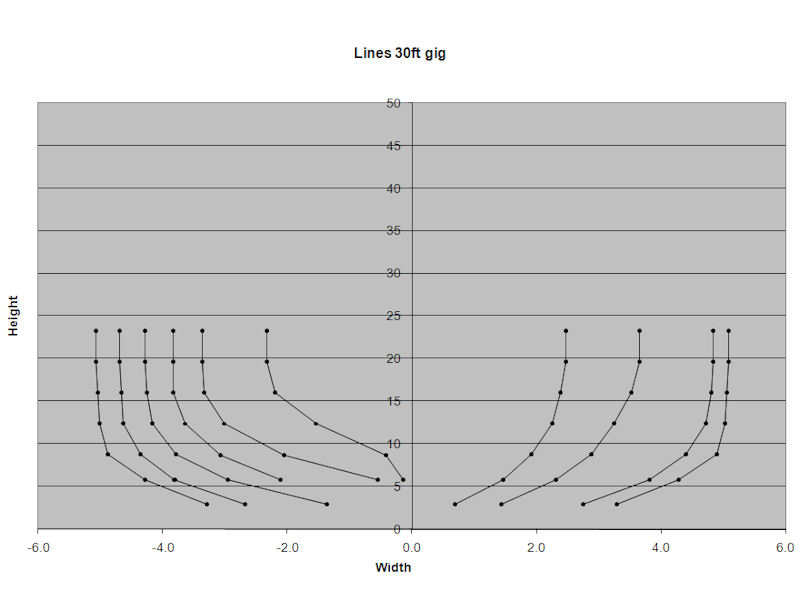

– Added 1 image of 30ft gig

19/02/23

– Added 40 ft Royal Barge, 2 scans, 1 IWM link

17/12/22

– split 45ft motor launch into standard and light type pages

11/11/22

– Added image of 27ft whaler in Gibraltar, 1938

– Added 30ft gig, added one image

06/11/22

– Added image of a 35 ft Fast Motor Boat Type I from HMS Southampton

– Added image of a 35 ft Fast Motor Boat Type II from HMS Superb

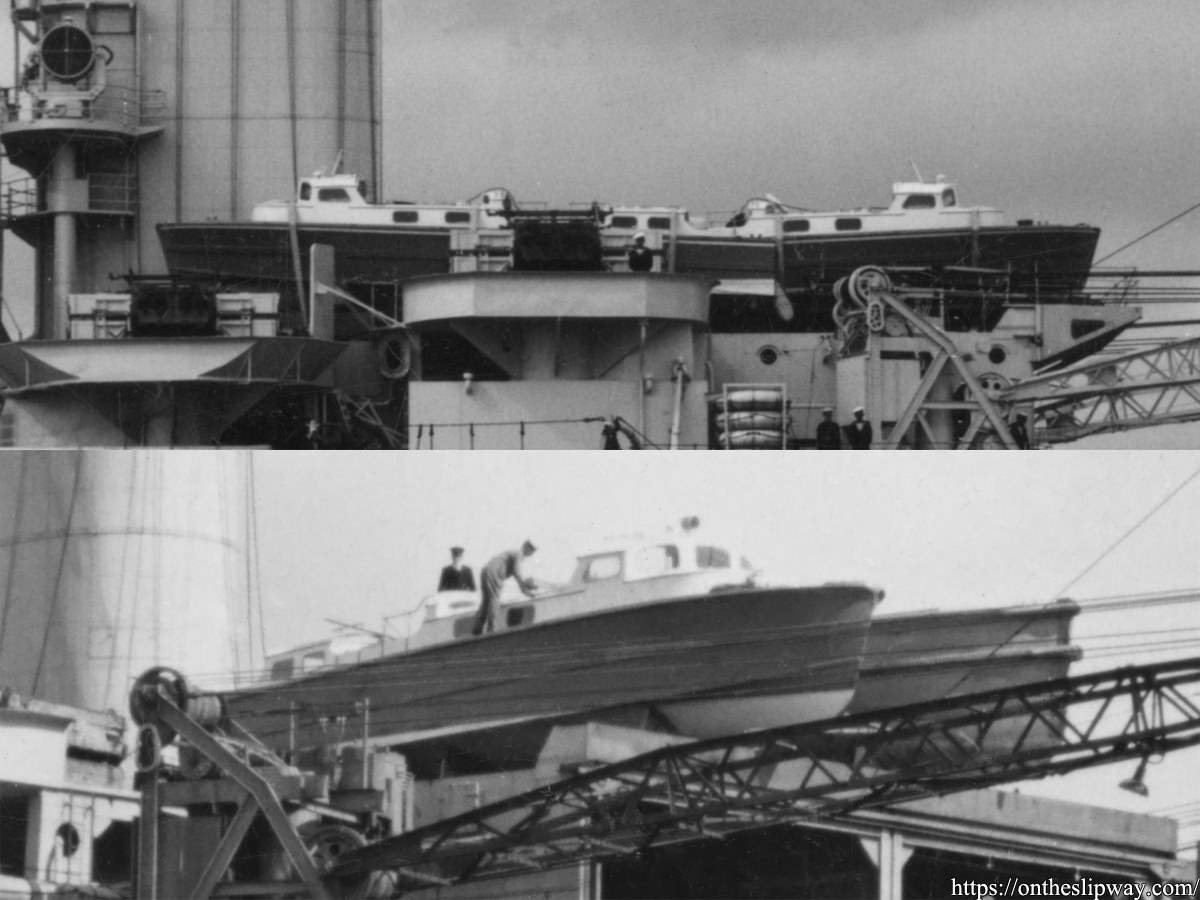

– Added image of two 45 ft Fast Motor Boats Type II aboard HMS Repulse.

08/06/22

– Added image of King George V and Admiral Jellicoe in a 50 ft Steam Picket.

01/06/22

– Added thee images of HMS Vanguard’s 45 ft Diesel Picket

08/03/22

– Added (same) overpriced image of HMS Ramillies’ on both 50ft Steam Picket and 45 ft Motor launch pages

07/03/22

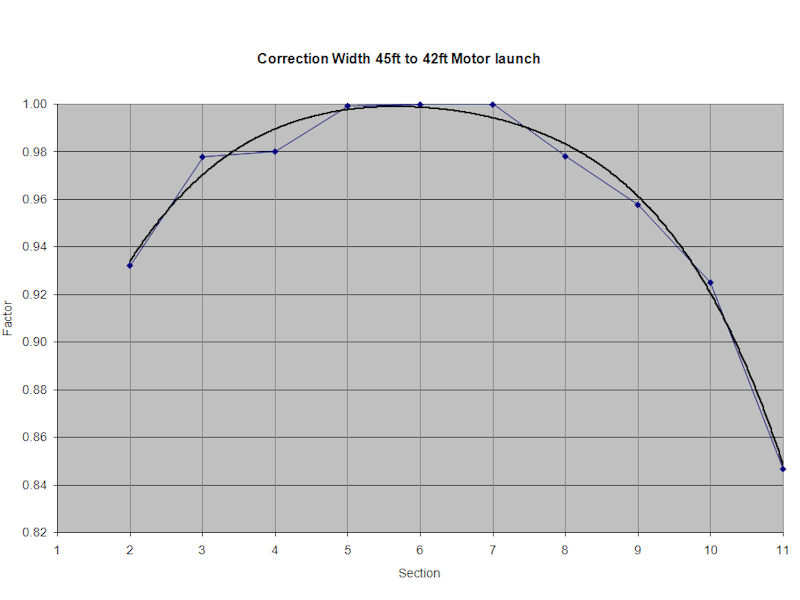

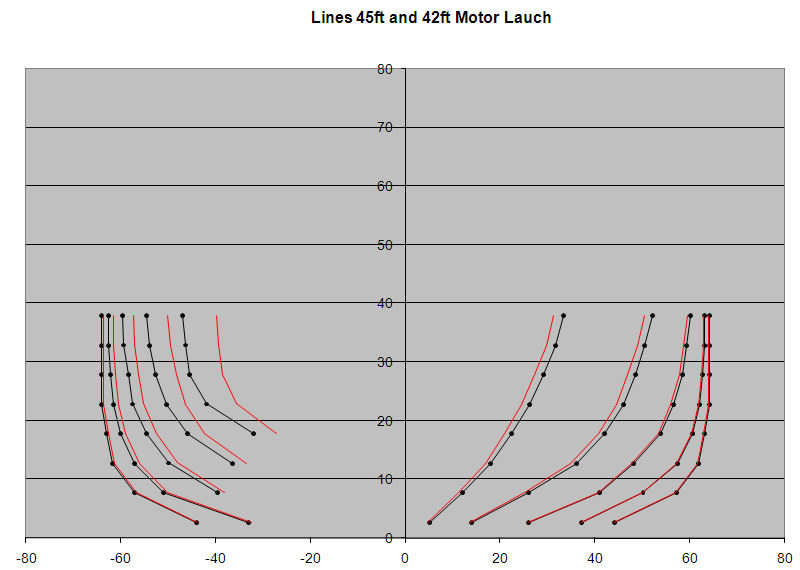

– 42 ft Motor Launch: blank page added. Adding comment to it and 45 ft regarding number of rubbers at the side (1 and 2 for the 42 and 456 ft respectively)

27/02/22

– 45ft Diesel Picket: adding ref. to history.naval.mil of Somerville’s barge (?)

30/11/21

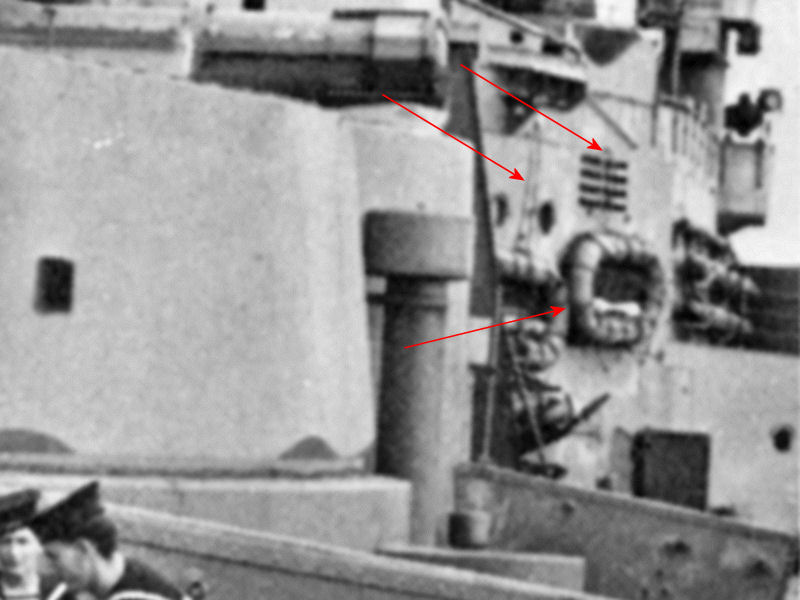

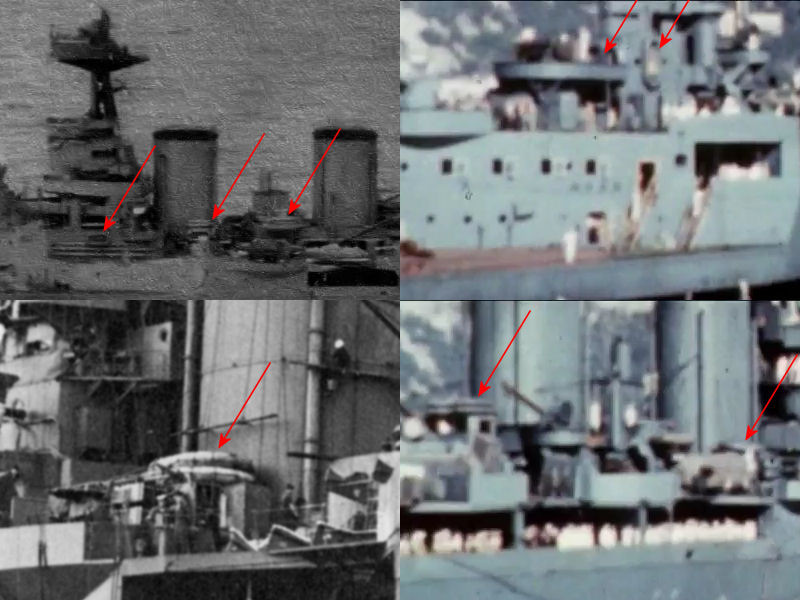

– Carley floats; 2 image added (Sheffield/Victorious)

26/10/21

– 35 ft Fast Motor Boat type 2, one image added

24/10/21

– Added Night Life Buoy, four images

22/10/21

– Added Balsa raft, two images

03/07/21

– Added 37.5 ft RAF Seaplane Tender, one image

– Added 35 ft Fast Motor Boat type 2, one image

27/05/21-

– Added 30 ft Fast Motor Boat, two images

15/05/21

– Added IWM A 8404 to 35 ft Fast Motor Boat type 1

18/01/21

– Added 45 ft Fast Motor Picket Boat (Thornycroft), GA from Lavery’s Churchill’s Navy.

– Added 45 ft Fast Motor Boat – Type II (British Power Boat). Moved images of wrongly ID’s images from 35 ft Fast Motor Boat Type I to this page.

14/01/21

– Added image of Rodney’s 27ft Whaler Picket

– Added images of Resolution’s & Nelson’s 50ft Steam Picket

– Added Rafts & Floats, Denton Raft & Carley Floats.

11/01/21

– Added remarks from info sheets to all posts

– Indicated drawing of the 45ft Motor Launch is of the light type only.

09/01/21

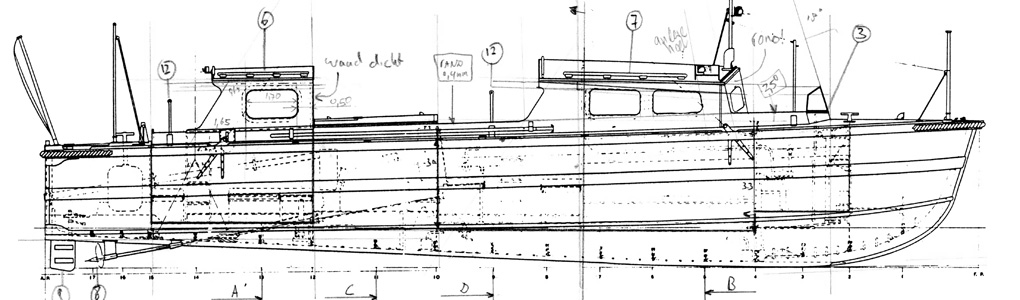

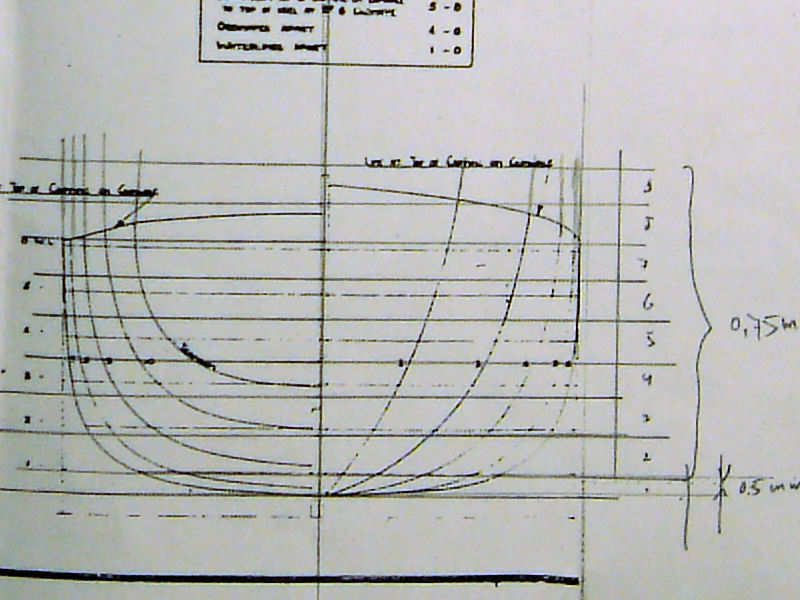

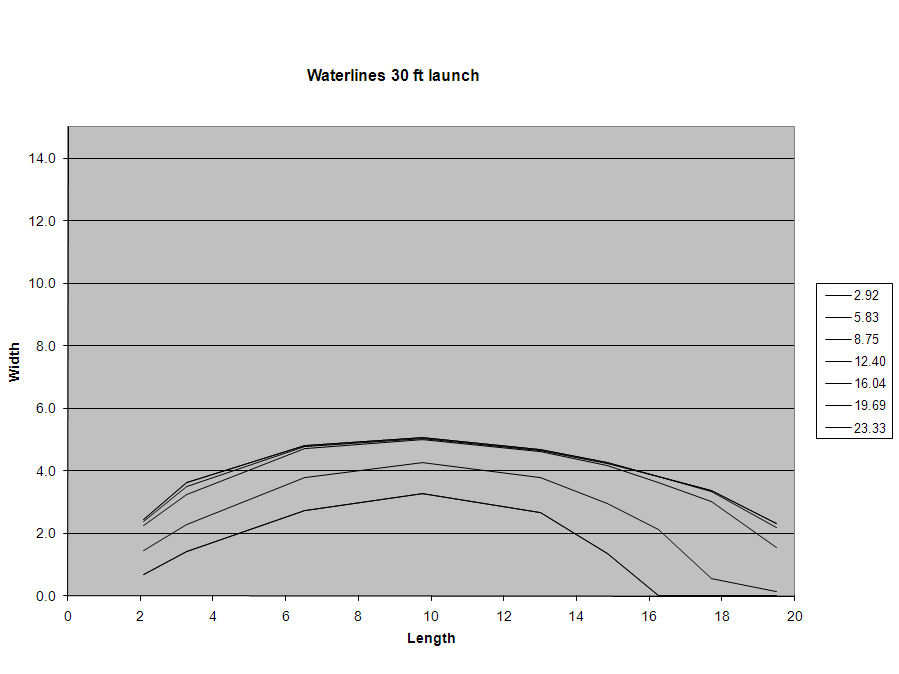

– Added 30 ft Motor Pinnace, GA, lines (no info sheet available)

– Added 32 ft Motor Cutter, GA

– Added 35 ft Fast Motor Boat type 2, GA, lines, info sheet

– Added 36 ft Harbour Launch, GA, info sheet

07/01/21

– Added 35 ft Motor Pinnace, GA, lines, info sheet

– Added 36 ft Motor & Pulling Pinnace, GA, lines, info sheet

06/01/21

– Added 14 ft Sailing Dinghy (placeholder)

– Added 30 ft Gig (placeholder)

– Added 50 ft Steam pinnace (placeholder)

05/01/21

– added 25 ft Fast Motor Boat

– added 35 ft Fast Motor Boat type 2 (placeholder)

– added 35 ft Fast Motor Boat type 3

– added 45 ft Motor Barge

04/01/21:

– Page initiated

– Added 16ft FMB: GA, lines, info sheet

– Added 25ft Motor Cutter: GA, lines, info sheet

– Added 35ft FMB Admiral’s Barge: Image, IWM links

– Added 35ft FMB – Seaplane tender: IWM links

– Added 45ft FMB & Barge: GA, lines

– Added 45ft Diesel Picket: IWM links