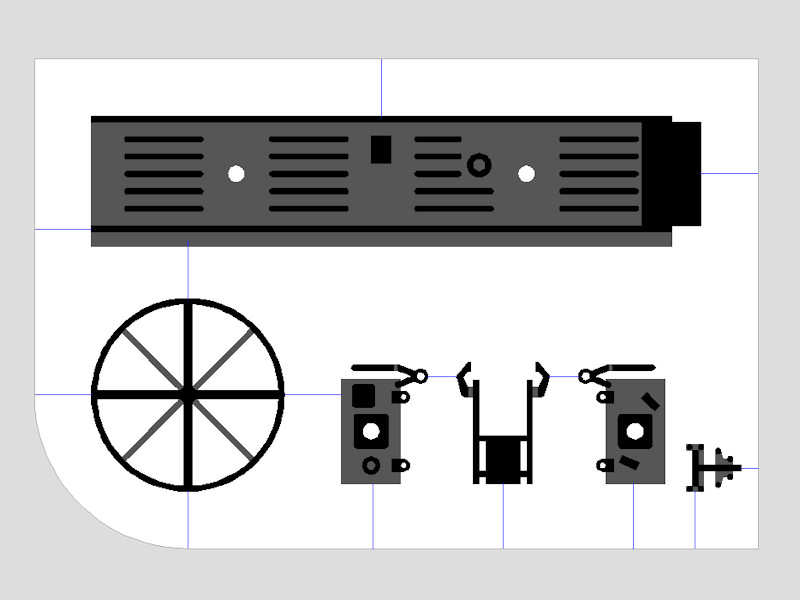

The Searchlight part I post showed how the searchlight frame was made including the design for the etched parts. The design is repeated here:

The lantern is mostly made up from etched parts with one large to-be-rolled strip and some additional detail parts.

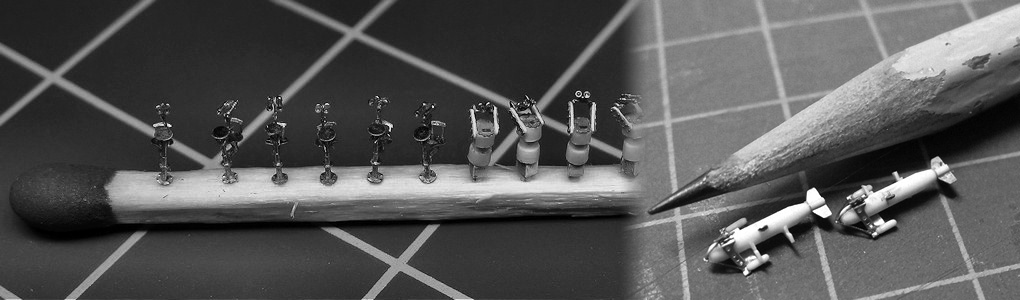

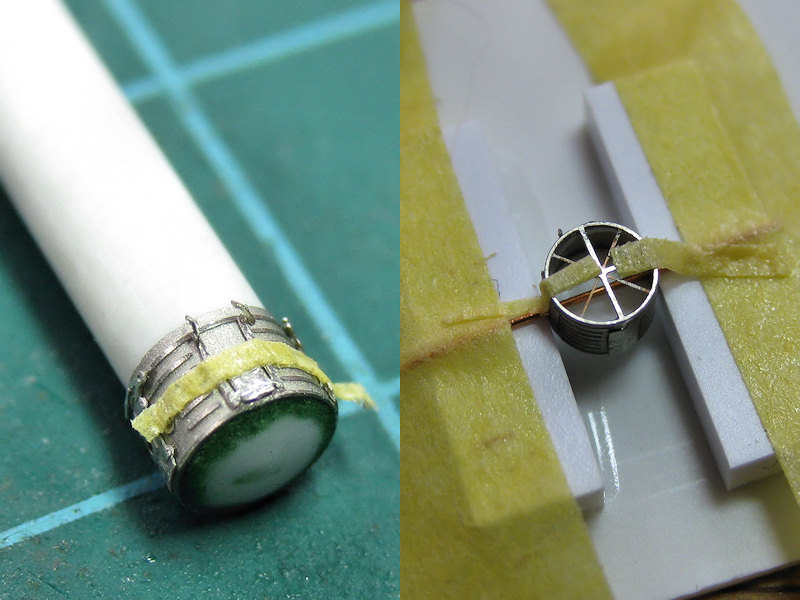

The rolling took some testing (made a few test lanterns first), but worked out well in the end. A stepped end cap was made with the lathe later sanded down to give the lantern its curved back.

The top detail has a small positioning block for the exact positioning (see top image, center, repeated on the rear surface of the detail part), the side parts are aligned on the lantern’s inclination axis. A small jig was made to hold the lantern in place while gluing the front detail into position.

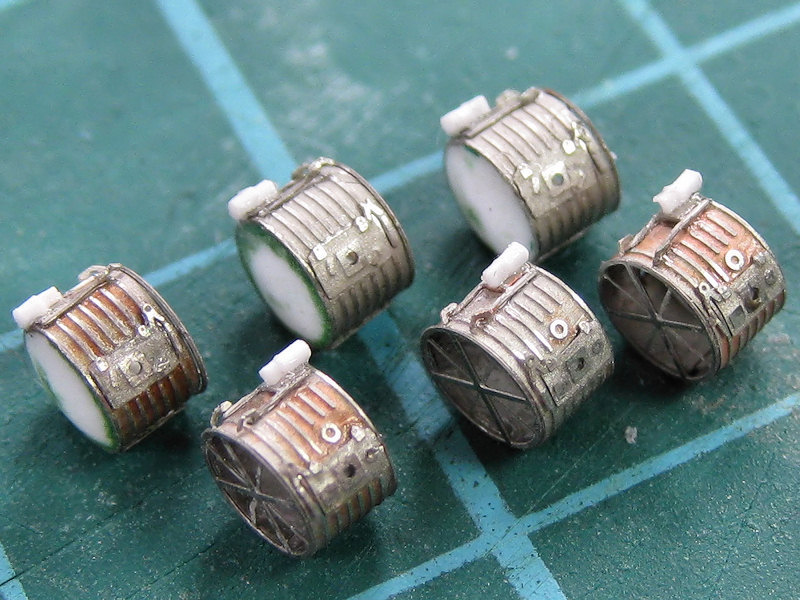

The parts on the side really add a lot of wonderful detail. The parts were first rolled into shape and then added.

And here are the completed parts. Some brass wire (0.1) is added to the lantern top. The searchlight can still rotate for ease of painting. I doubt the inclination axis (i.e., small brass wire) will be visible after painting as a) the searchlights were usually set looking downward and b) I think I’ll add some glazing material to the PE front.